WFI Plant

PAM PHARMATECH is manufacturing high quality equipment water for injection (WFI) plant designed to produced 100°h pyrogen free sterile distillate & chemically pure confirms to IP/BP/USP standard.

Multicolumn distilled water plant works on the principle of interstate heat exchanger, dramatically reduce the consumption of heating energy and cooling water. Thus enable to produce a large volume of pyrogen free distillate at a fraction of the cost than conventional systems. All documents related to factory

acceptance test (FAT), Installation Qualifications (IQ), Operation Qualification (OQ), PQ are provided as part of the operational manual.

Salient Features

Pure, Sterile & pyrogen free distilled water conforms to IP/BP/USP standards.

Fully automatic operation. no attendant required.

Energy Saving Low operating cost.

All Contact parts are S.S. 316L and all joints are sealed with teflon gasket Improved condenser cooler design for optimum efficiency.

Electropolished creviceless inner contact surfaces.

Sanitary triclover fittings for quick and easy preventive maintenance.

Standard Scope of Supply

Multistage feed water pump fabricated with type 316 stainless steel.

Maximum pressure -8 bar.

Stainless steel centrifugal pump for cooling water transfer.

2 Nos of rotameter for feed water and cooling water.

Conductivity meter for feed water and final WFI.

Above 80 LPH Plant

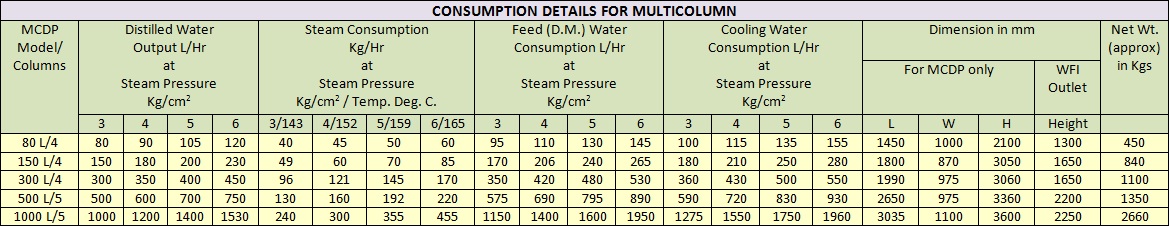

Consumption Details